News

Finer Points of Manufacturing Medical Stents

November 21, 2014

In addition to selecting the right laser, machine, processing technique, and assist gas, successful manufacturing of medical stents also depends on the choice of process tool.

One of the most common laser micro-machining applications is the manufacture of medical stents. These small and intricate wire mesh tubes insert into diseased coronary arteries to improve blood circulation.

Basis for the selection of the materials used for manufacturing medical stents are on their mechanical and corrosion resistance properties. Popular materials include low carbon 316L stainless steel, Nitinol, MP35N, tantalum, and platinum. Approximately 70% of all stents are manufactured using low carbon 316L due to its relative ease of fabrication, availability, low cost, and good mechanical and biological properties. However, cutting of all these materials is very effective when using lasers.

As stents insert, permanently, into arteries, it is imperative that the cut metal does not have rough edges or accumulated dross that could result in infection. With tube diameters between 1mm and 10mm and a wall thickness of around 100µm, they require high precision processing to maintain their intricate structures. The two primary requirements are low dross levels to minimize post-processing times and a small kerf width (20µm to 30µm) to make the specialist cutting of very intricate patterns possible.

Before the advent of fiber lasers, pulsed Nd:YAG lasers were often the go-to process for this application. At the time, the high energy densities and focused spot size of around 30µm made it best suited for fine cutting.

However, the diffraction limited beam quality of fiber lasers represented a real breakthrough for the industry. A study by Meng, et. al. (2009), demonstrated that cutting quality (heat affected zone and average roughness) was better with a fiber laser compared to an Nd:YAG laser due to its single mode output and small focused spot size.

Unlike Nd:YAG lasers, fiber lasers comprise fused components, meaning the performance is not dependent on the alignment of rods and mirrors. For manufacturers, this eliminates the need for time-consuming routine maintenance. The absence of water-cooled pump chambers also negates the risk of leaks that could cause the rods to fail, incurring further service costs. In addition, the use of a doped fiber as the gain medium in fiber lasers results in intrinsically excellent beam quality.

JK Lasers’ 100W fiber laser, the JK100FL, produces very small spot sizes below 10µm, making it an ideal solution for intricate implantable devices such as stents and other medical tubes. The creation of dross-free cuts (20µm kerf width) combined with very high contour accuracy (<5µm), vastly reduces the amount of post-processing that is required.

Modulating the pulse frequency and pulse duration of fiber lasers can significantly improve the controllability of fine cuts. JK Fiber Lasers feature a pulse generator on the control card, which allows them to run in a modulated mode. This can easily be controlled using JK Lasers’ integrated FiberView software, which can create and select between pulse shapes.

The choice of assist gas plays an important role when manufacturing medical stents. When using oxygen, brittle oxides can form, resulting in cracks in the stent surface and higher dross levels. Popular inert gas choices for stent cutting include argon, helium, and nitrogen. When cutting with inert gases, the cutting speed reduces but the cut quality is better. Typical cutting speed for 0.5mm 316L stainless steel with single mode laser output, Gaussian beam profile, and nitrogen assist gas is approximately 500mm/min.

Dr. Mohammed Naeem, global key account manager for JK Lasers, explains: “Precise, highly controlled processing is critical when micro-cutting stents. Featuring exceptional beam quality and inherent stability, lower powered fiber lasers such as the JK100FL and JK200FL can quickly and accurately cut small, intricate devices.”

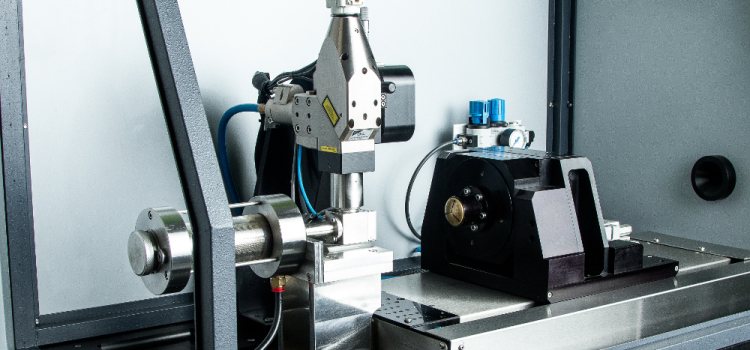

Although fiber lasers offer better beam quality and pointing stability when compared to traditional Nd:YAG lasers, the quality and speed of the cut will ultimately depend upon the system into which it is integrated. To realize the full potential of fiber lasers, system integrators will often use granite or polycast bases to help dampen vibration.

Precision Automated Laser Systems (PALS) integrates JK Fiber Lasers into its precision tube cutting systems. Owner Richard Swindell says: “The high quality beam delivery and integrated software of JK Fiber Lasers enables us to manufacture more reliable systems. From machine to machine, the componentry is more consistent, so the quality and repeatability is really high in medical device applications.”

A potential risk associated with micro-machining small, thin tubes, is back wall damage. Ejected hot particles from the cut kerf can adhere to the opposite wall of the tube, causing a rough surface finish. According to Muhammed, et. al. (2010), using wet cutting can overcome this issue.

Wet cutting involves the supply of a continuous water stream to minimize heat transfer to the back wall and to carry hot particles away after ejection from the cut kerf. The researchers found that obtaining clean, spatter-free back walls is possible when wet cutting stainless steel 316L tubes using a JK100FL in a stent-specific system.

PALS’ machines are capable of both wet and dry cutting. Swindell explains: “Wet cutting is beneficial when processing tubes measuring between 0.025″ and 0.175″ in diameter. In these cases, it can prevent the laser beam from damaging the back wall.

“However, when processing diameters less than 0.020″ or above 0.175″, wet cutting is not really viable. Either the bore is so small that water cannot force through it, or it is so large that back wall damage is no longer an issue. In these instances, dry cutting is a viable option.”

In addition to selecting the right laser, machine, processing technique, and assist gas, the successful manufacture of medical stents also depends on the choice of process tool. For single mode fiber lasers using a typical 1:1 imaging onto the workpiece, the Rayleigh range is below 100µm. To optimize kerf width and cut quality, the focus position must be fine-tuned. JK Lasers’ process tools feature built-in fine focus adjustment and optimization, so production of a parallel and lamina gas flow works for dross free cuts.

When using wet cutting, PALS’ precision tube cutting systems feature a captured cutting option, which uses a chamber instead of a nozzle to deliver gas to the material. This set-up allows the orifice created by the laser puncturing the material to act as the nozzle. As it is in a chamber, the assist gas cannot escape until the material is punctured. This delivers higher gas efficiency, generates a smaller heat affected zone, and creates kerf widths as small as 13µm.

Beyond their processing capabilities, fiber lasers offer manufacturers many other benefits. The diode laser pump sources used in JK Fiber Lasers, for example, are extremely reliable. With a mean time to failure (MTTF) of more than 300,000 hours, they save manufacturers money by helping to extend system lifetimes.

Fiber lasers have a much smaller footprint than Nd:YAG lasers, meaning they can integrate into systems that are more compact. These, in turn, can fit, easily, into laboratories where space is at a premium.

As fiber lasers are up to 10 times more energy efficient than traditional laser sources, they can help dramatically reduce production facility running costs. The generation of less heat means, in the case of air-cooled systems, that there is less demand put on on-site air-conditioning. Realization of savings also comes with the use of laser diode pumping at high conversion rates, delivering wall-plug efficiencies of more than 25%.

Finally, laser cutting is a non-contact process that eliminates the risk of damage to the workpiece. Compared to the mechanical wear that may occur when using other equipment, lasers help improve the economy of manufacturing applications by increasing the lifespan of the tool, as well as the reliability and repeatability of the end results.

*Source http://www.onlinetmd.com/tmd0612-medical-stents-manufacturing.aspx#.VMELrEdSyRV

back to news